Discover our set of Servo Motor Drives, where the best quality meets unimaginable affordability. Created using the latest technology, these goods provide unprecedented performance at prices that match your pocket. Regardless of whether you are going into automatics, robot-making or industrial equipment manufacturing; this universal remedy guarantees smooth control and absolute dependability throughout the process. Having been made strong and meticulously crafted; these servo motors guarantee accuracy as well as durability in equal measure for extended periods. With our unmatched offer on servomotor drives technology, you can now make your operations more efficient than ever before while saving lots of money in return!

Efficiency often requires optimization of space utilization since most times spaces available may not be adequate enough for achieving desired levels hence limiting performance; however Jiesheng considered these challenges when designing their servos motors systems therefore coming up with compact models that occupy small footprints without compromising on quality or output power ratings – making them ideal choices where real estate is at premium. Our servo motor drive systems may look small in size but don’t let this fool you because they are capable of delivering precise control with unmatched efficiency levels! We can help optimize production lines as well as upgrade robotic workstations through providing customized solutions which combine aesthetic appeal with functionality thus ensuring maximum gains in terms of output while minimizing energy consumption or wastage.

In the current fast-paced industrial environment, precision and efficiency are everything. Jiesheng servo motor drive technology is designed to tackle this problem head on. This technology is at the forefront of automation in industries across the board. With a Jiesheng servo motor drives system running things, businesses can expect nothing less than exceptional performance, reliability and adaptability. Our servo motor drives have been designed with meticulous attention-to-detail so as to cater for different demands of modern manufacturing industry where accurate motion control is required together with seamless integration into existing systems; be it robotic arms or conveyor belts among others – they enable organizations achieve highest levels of productivity and efficiency thus setting new benchmarks for industrial automation solutions.

Jiesheng understands that no two industrial applications are the same; hence we offer tailored servo motor drive solutions based on customer specific requirements such as speed variation demand, torque regulation dynamics among other things so that our clients get what is exactly needed for their machinery performance optimization needs. This flexibility in design enables integration between Jiesheng servos motors and other automation components to achieve seamless communication during operation. For instance; if there is need for a perfect fit between Jiesheng servo motor drives (which have precise speed control) artificial intelligence powered predictive maintenance algorithms can be incorporated into them thus creating intelligent machines capable of self-monitoring and self-repairing themselves whenever necessary – leading to improved reliability levels which translates into higher productivity rates within any given timeframe.

We believe that innovation should never stop growing thus we continuously strive to break new grounds when it comes to servo motor drive technology which will meet future demands posed by emerging industries tomorrow. Scalability features were taken into account during development process so as provide adequate room for growth along with compatibility towards upcoming technologies coupled together with changing standards within industrial sectors served by our products. Whether its about incorporating IoT connectivity through wireless networks or even wired ones including ethernet cables among others used for real-time monitoring purposes during operation phases; all these forms part of Jiesheng’s solution offerings under this category since they are designed keeping mind adaptability across different application needs which may arise overtime. With us you are not just getting a servo motor drive solution but investing into future success of your business.

In 2009, Guangdong Jiesheng Electric Technology Co., Ltd. was established. It is a high-tech enterprise that specializes in the production of inverters, servomotors, servo drives, PLCs and stepper sensors; with 15 years’ experience in automated programs. Our R&D department is separate from other departments which enables us to support OEM as well as ODM too. The company’s products have achieved CE certification together with ISO9001 quality management system certification among others such as FCC approval marking & ROHS compliance etc.

The company is located in Foshan city which lies at the center of south China’s Jiangnan region near Hong Kong and Macao SARs thus convenient for international trade exchanges. There are over ten thousand square meters land which has been built into an independent science park by the company itself while another twenty thousand square meters science park phase II is under construction now covering an area around 10 mu so far . Apart from this main office branch offices were set up successively in Jiangsu province and Shandong province respectively etcetera .

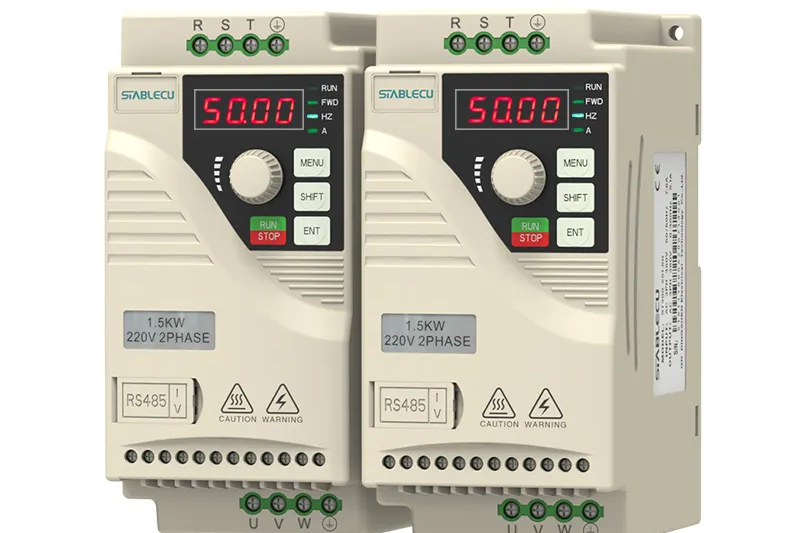

Efficient energy utilization for diverse applications.

Seamless transition between power frequencies.

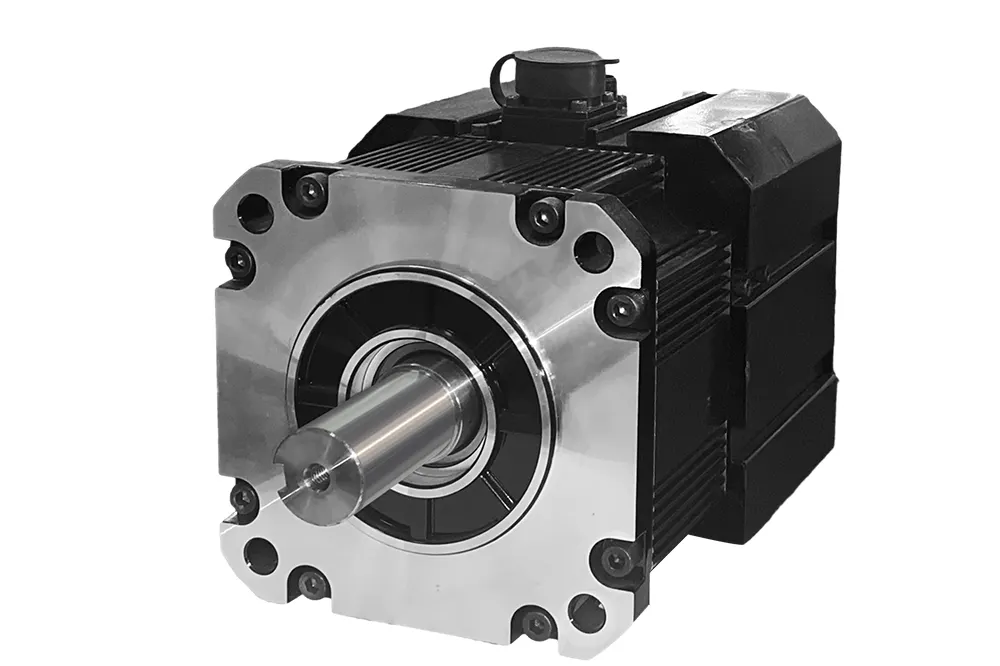

Precise control for dynamic motion requirements.

Optimal speed regulation for varying loads.

28

Apr

28

Apr

28

AprServo Motors with Drives find applications in a variety of industries such as manufacturing, robotics, automation, CNC machining, packaging among others. They are often employed where there is requirement for exact position holding at different loads or speeds along with high torque capability

Position feedback from the rotor shaft of a Servo Motor is continuously monitored by its driver circuit using an encoder or resolver mechanism then compared against desired value represented by input signal before any necessary corrections can be made through output commands sent to actuator part connected directly onto load being moved. This feature allows system to maintain precise positioning even when external force acting on it changes direction or magnitude abruptly

Among advantages offered by Servo Motors fitted with their own drives include very great precision levels achieved during operation, fast response times exhibited as well dynamic speed controls realized coupled together high torque density capabilities. Moreover such devices permit flexibility in terms of programming options thus making them suitable for use across wide range of applications.

In selecting right kind of Servo Motor that has a Drive one must take into account factors like torque requirement, speed range variation desired positional accuracy environmental conditions prevailing around where it will be deployed integration possibility vis-à-vis already existing control systems etc., if unsure about this process consult supplier/manufacturer representative who should provide guidance based on their expertise within field concerned.

Yes, they can. Servo Motors with Drives are designed for easy integration into existing systems and machinery. They come typically provided with standard communication protocols together various mounting options which facilitates smooth blending them different types of control architectures or equipment structures; besides many manufacturers offer ample technical support as well comprehensive documentation that aids troubleshooting during integration stage.

Servo Motors with Drives typically require minimal maintenance due to their ruggedness and sophistication. However, it is advisable to inspect parts like bearings, belts and cables regularly for optimum performance and avoidance of possible problems. Besides this, it also helps if you keep the environment around clean to prevent dust or any other particles from getting into the servo system as they might shorten its life span.

Though designed for use in a variety of environments such as factories among others; extreme temperatures, humidity levels, dust concentration or vibrations could affect the performance and durability of Servo Motors with Drives. In order to ensure that these machines operate reliably in harsh environments it is necessary that appropriate IP rating servos are chosen together with protective enclosures and sealing arrangements where applicable. Furthermore periodic checks should be made through preventive maintenance routines on environmental factors induced faults .