Unearth our Servo Driver that increases the command and accuracy of your movement mechanisms. It is made with advanced technology that gives it unequalled performance for applications which require a lot. Either in manufacturing or robotics; this servo driver guarantees smoothness and precision in motion control thereby resulting into highest efficiency as well as dependability. Change over to systems of supreme accuracy and efficiency – open up fresh avenues for exploration using our sophisticated servo-drive technology solution!

We understand how important it is for devices like these to operate continuously without ever breaking down since their failure might lead into catastrophic consequences in industries where human lives are at stake hence why our servo drivers were created not only to meet but surpass industrial standards when being used under harsh environmental conditions. For example, some places experience extreme temperatures while others have high humidity levels or even dust particles floating around everywhere and if such factors were left unattended then no one could guarantee what would happen next once those machines started malfunctioning due to continuous exposure thus leading us towards providing reliable solutions throughout your operations while ensuring peace of mind knowing that everything will run smoothly until power off.

The best way of connecting servo drives into your setup is finding something that can integrate easily without causing any problems thereafter because failure brings more harm than good even though they might seem helpful during installation at first sight hence making sure all components match each other perfectly since there are situations where incompatibility brings about failure otherwise everything should function flawlessly under normal circumstances thus reducing downtime significantly although sometimes some tasks take longer than expected due to various reasons including improper programming besides having few or no knowledge at all concerning them before starting working on such projects but once again seamless integration would solve everything quickly thereby leading us towards achieving desired results sooner rather than later while striving hard not only towards meeting but exceeding customer satisfaction every single time.

We can never stop advancing our products because we know very well that technology is always improving day by day thus making it impossible for us to rely on the same old things forever; henceforth this should act as motivation towards coming up with new features such as adaptive control algorithms which are capable of monitoring real time events together with predictive maintenance functionality so that in case anything happens then appropriate action can be taken before everything crashes down around someone’s ears but remember that these machines work automatically without human intervention most times so they have been programmed accordingly meaning that even without any input from people they would still operate normally until shutdown commands were issued therefore there was no need worrying too much about failures caused by lack of timely servicing especially when dealing with machines designed using this kind of technology.

Our servo driver is the most accurate one on the market and it never fails. For example, if you have a robot or an automated system that needs precise motion, this is what you need. Wherever used in manufacturing, robotics or automation, our servo drivers guarantee smooth and exact movement which maximizes performance as well as efficiency within any device or machine. Therefore, it can be concluded that the above mentioned equipment ensures accuracy like no other.

In 2009, Guangdong Jiesheng Electric Technology Co., Ltd. was established. It is a high-tech enterprise that specializes in the production of inverters, servomotors, servo drives, PLCs and stepper sensors; with 15 years’ experience in automated programs. Our R&D department is separate from other departments which enables us to support OEM as well as ODM too. The company’s products have achieved CE certification together with ISO9001 quality management system certification among others such as FCC approval marking & ROHS compliance etc.

The company is located in Foshan city which lies at the center of south China’s Jiangnan region near Hong Kong and Macao SARs thus convenient for international trade exchanges. There are over ten thousand square meters land which has been built into an independent science park by the company itself while another twenty thousand square meters science park phase II is under construction now covering an area around 10 mu so far . Apart from this main office branch offices were set up successively in Jiangsu province and Shandong province respectively etcetera .

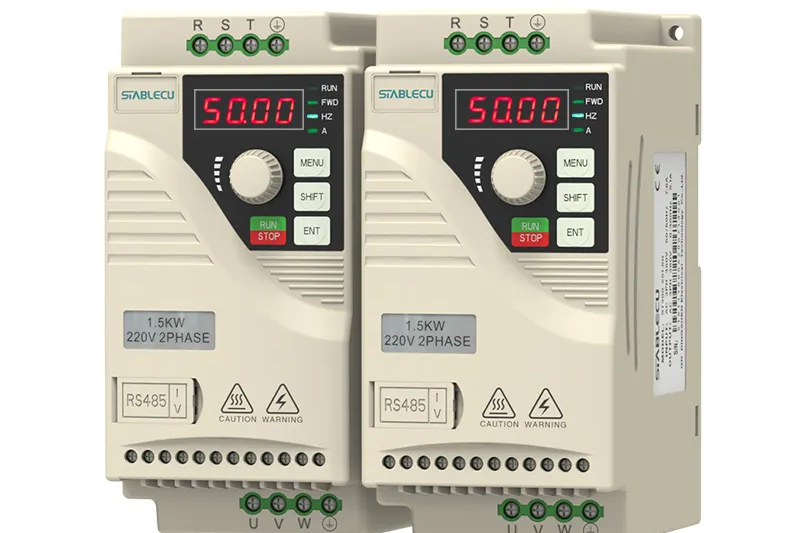

Efficient energy utilization for diverse applications.

Seamless transition between power frequencies.

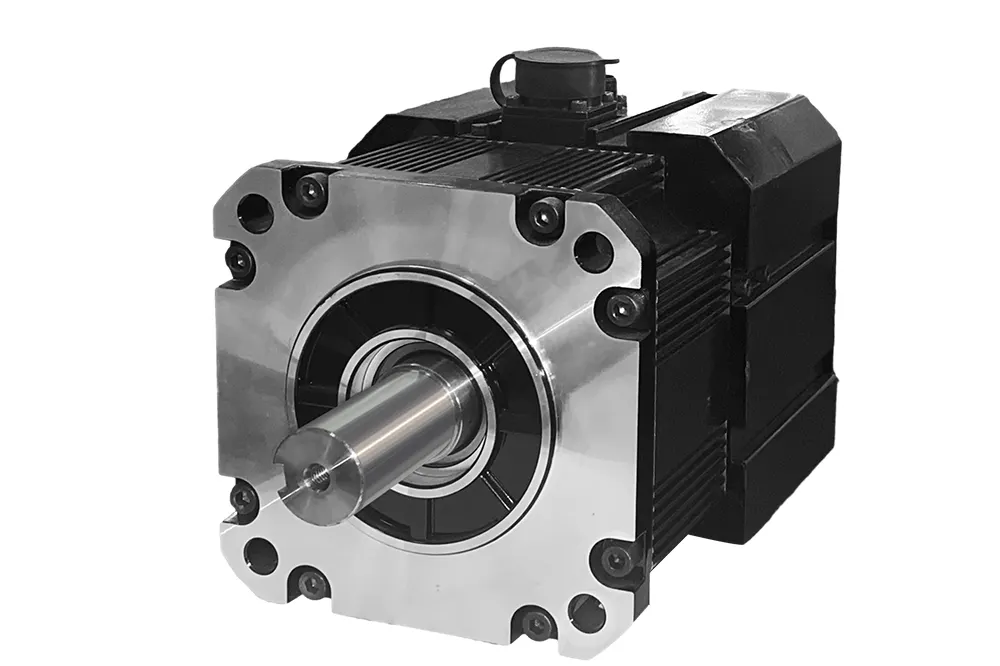

Precise control for dynamic motion requirements.

Optimal speed regulation for varying loads.

28

Apr

28

Apr

28

AprThe mechanism that controls the movement of a servo motor by getting signals from a controller is called a servo driver. It changes the speed, direction, and position of the motor in response to its input signals.

Our servo drive has control algorithms for accurate motion control, fast speed performance as well as compatibility with different types of servos motors. Moreover, it also features easy integration robustness reliability and comprehensive protection functions.

Our servo drivers can be used in various fields including robotics systems; CNC machines tools; automation plants; 3D printers etcetera Any application that needs accurate dynamic motion control will benefit from our products.

To choose an appropriate one you need to consider things like what kind of motor do I have? What is its torque rating? How fast must this system move? Does it need high accuracy positioning or just general purpose use? Our team would help guide through these questions towards finding best fit for each customer’s situation

Yes! We offer modifications services where by communication protocols voltage ratings or even control interfaces may be altered to suit clients’ specific requirements thus coming up with a more personalized solution which perfectly meets their unique needs.

YES! We have got comprehensive technical support documentation such as user manuals datasheets application notes etc., all aimed at assisting users during installation set-up operation stages . Additionally there exists also around-the-clock access to our dedicated service personnel who should help answer any queries customers might raise concerning usage issues encountered along way while utilizing said devices.

Certainly Yes! Our device was designed having in mind compatibility with wide array such controllers PLCs HMI interfaces feedback devices among others meaning that it can easily fit into existing systems or even be used as part of a new motion control solution.