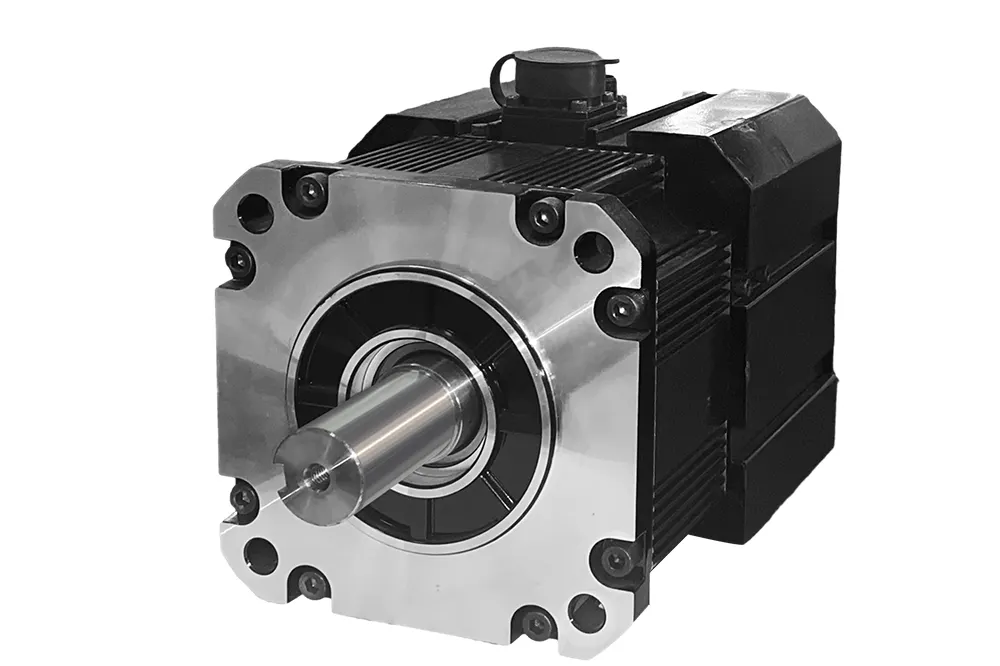

Unearth our best-in-class servo motor solutions that are built to enhance your operations. We provide a wide variety of servo motors which are made to cater for different needs, backed with expert support and high quality standards. This can be in terms of accurate positioning; quick start and stop or smooth engagement with other systems; everything is made possible by use of up-to-date technology on offer here – no matter what you need it for! You can count on us for dependable performance at all times along the journey to cost savings as well as accuracy improvements where required most. Feel free now therefore, try out one of these amazing devices today itself!

In 2009, Guangdong Jiesheng Electric Technology Co., Ltd. was established. It is a high-tech enterprise that specializes in the production of inverters, servomotors, servo drives, PLCs and stepper sensors; with 15 years’ experience in automated programs. Our R&D department is separate from other departments which enables us to support OEM as well as ODM too. The company’s products have achieved CE certification together with ISO9001 quality management system certification among others such as FCC approval marking & ROHS compliance etc.

The company is located in Foshan city which lies at the center of south China’s Jiangnan region near Hong Kong and Macao SARs thus convenient for international trade exchanges. There are over ten thousand square meters land which has been built into an independent science park by the company itself while another twenty thousand square meters science park phase II is under construction now covering an area around 10 mu so far . Apart from this main office branch offices were set up successively in Jiangsu province and Shandong province respectively etcetera .

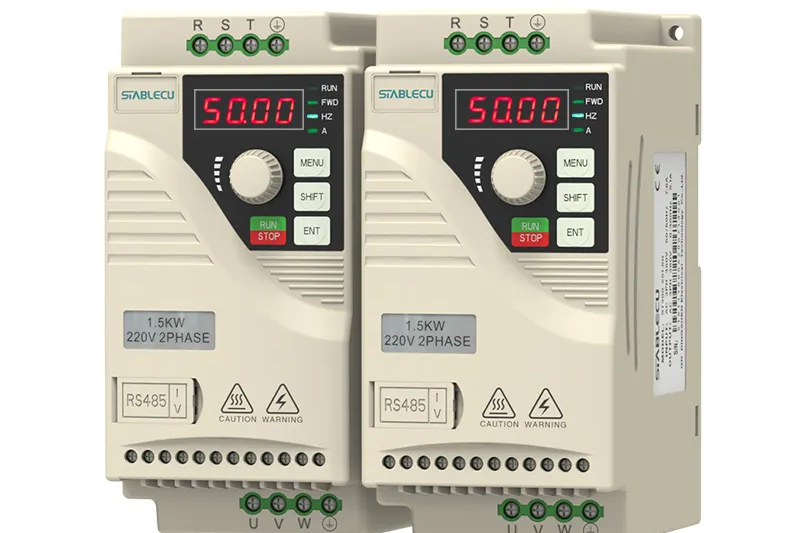

Efficient energy utilization for diverse applications.

Seamless transition between power frequencies.

Precise control for dynamic motion requirements.

Optimal speed regulation for varying loads.

28

Apr

28

Apr

28

AprA servo motor is a rotary actuator that permits precise control of angular position, velocity and acceleration. Unlike common motors, they include feedback mechanisms such as encoders or resolvers which enable them to achieve accurate and controlled movement.

Industrial servos offer greater precision than any other type of motor available today; they also provide better speed and torque control too. Servos are good for operations that need very exact positioning, quick acceleration or smooth operation at low speeds. Also, servos are highly efficient with ability to adapt widely varying loads under different operating conditions.

Feedback devices like encoders or resolvers give instantaneous information about where the output shaft of a servo motor actually is in relation to where it should be moving towards (position) as well as how fast this change happens (velocity). This data gets continually compared against desired values for position / velocity so that necessary adjustments can be made by the servo until accuracy is achieved.

When selecting an appropriate type of servomechanism drive based on your needs there are several things you have to keep in mind: required torque range; necessary speed range; whether environment will be dusty/dirty/wet; space limitations – compact size vs powerful performance requirements; integration into existing control systems – compatibility issues should not arise due their close interaction between each other during operation.

Yes, we can use them especially where superior responsiveness matters most i.e., robotics, CNC machining centers as well as other automated manufacturing systems designed for high-speed production lines . The capability of achieving accurate control over position, velocity and acceleration makes them unbeatable when working under such conditions where accuracy is highly demanded so that product quality remains consistent throughout entire process.

For optimum performance levels coupled with prolonged lifespan, all servo motors should be kept in good condition through proper maintenance practices; control parameters must also be tuned appropriately according to recommended settings while considering operating environment factors at play too . Moreover, one needs to select high-quality devices manufactured by reputable companies besides following strict installation guidelines plus observing safe operation procedures which could enhance reliability as well as durability.