Introduction to Variable Frequency Driver Applications

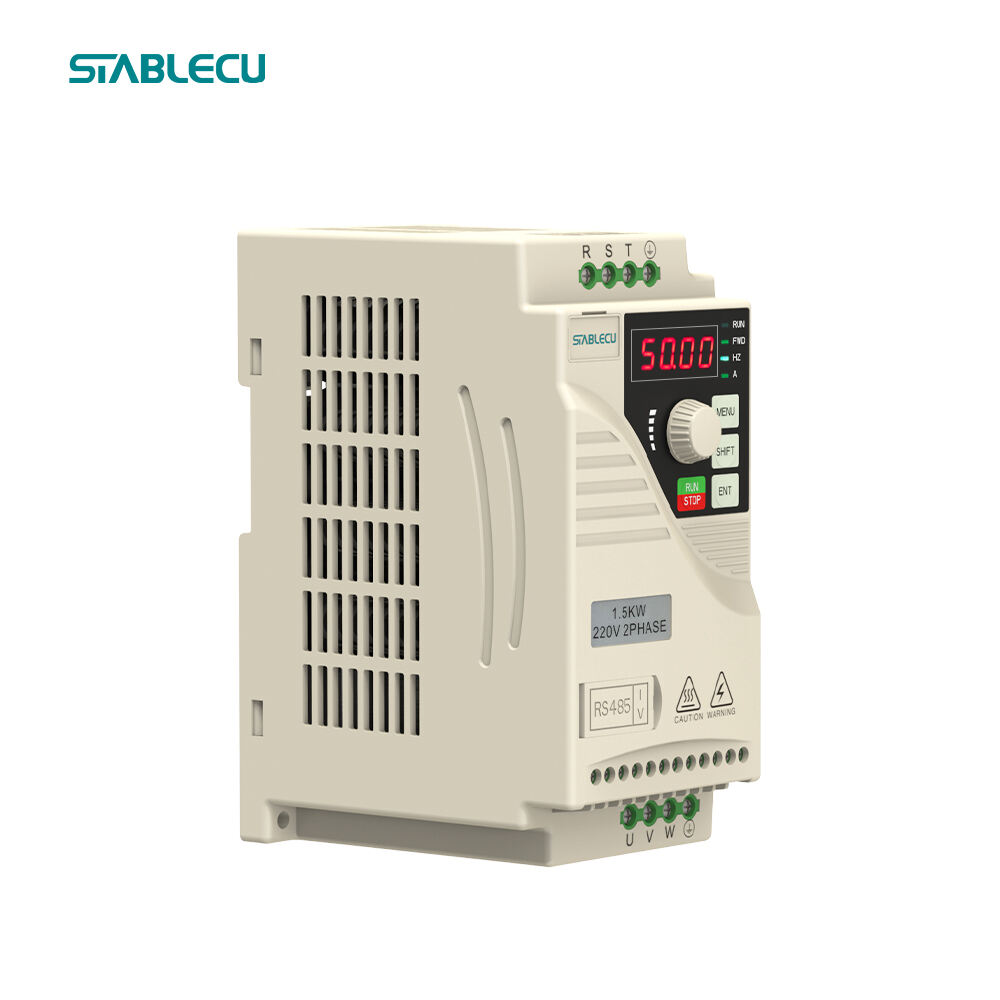

A variable frequency driver (VFD) is a kind of electric motor controller that assists in the regulation of the speed at which an AC electric motor runs. VFDs are able to control the engine’s rotational velocity, torque and horsepower by adjusting frequency and voltage supplied.

Features of Variable Frequency Driver

The ability of a variable frequency driver to save energy is one of its major characteristics. By lowering speeds when full power is not needed, motors can significantly reduce their energy consumption using variable frequency drivers. This cuts costs while enhancing environmental conservations.

Another important characteristic exhibited by a variable frequency driver is its flexibility. It can be programmed to meet certain requirements as well as automatically adapt to changes in conditions. For instance, in manufacturing environments, the speed of conveyor belts can be controlled based on market demand using a variable frequency driver.

Also, system efficiency is improved because of low mechanical strains thereby extending motors’ life spans which lead to lower maintenance expenses thus decreased downtime hence less abrupt fluctuations in power supply that may result into destructions due to these factors therefore they are called variable frequency drives because they regulate the frequency with which the current flows through them so that it matches up with how fast or slow you would like your car’s wheels spin around!

Benefits of Using Variable Frequency Driver

There are several advantages associated with application of VFDS in different sectors. In industrial areas, production processes can be optimized through accurate control over motor speeds by employing VFDS; this increases productivity while minimizing wastes.

In commercial buildings, HVAC systems can be operated more effectively by use of variable frequency driverS. Thus variable frequency drivers enable varying fan speeds based on heating/cooling demands thereby ensuring energy savings and comfort levels at optimum points simultaneously.

Additionally, variable frequency drivers also have applications such water treatment as pumps and filtration equipment where they help maintain adequate flow rates while conserving water quality standards too.

Applications of Variable Frequency Driver

Many industries utilize variable frequency drivers in a number of ways. For instance, the manufacturing industry employs them on conveyor systems as well as machine tools and material handling equipment. Oil and gas companies use VFDs in controlling flow rates or pressures in its pumps and compressors.

In construction, they are used to control hoist and crane lift speeds safely. These devices also govern the movement of the car up and down the elevator shaft smoothly.

Modern building management systems cannot be complete without VFDs because they assist in achieving optimal indoor climate control at minimum energy consumption levels.

Variable frequency drivers (VFD) have been widely used across various industries due to their excellent ability to accurately and efficiently control motor speed. From enhanced system efficiency to reduced power usage and costs; this has made variable frequency drives (VFDS) indispensable in many areas of application. As technological progress continues hand-in-hand with increasing awareness about environmental matters, variable frequency drivers will doubtless continue playing an important role towards sustainability ambitions all over the globe.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

KA

KA

BN

BN

LA

LA

TA

TA

KK

KK

UZ

UZ